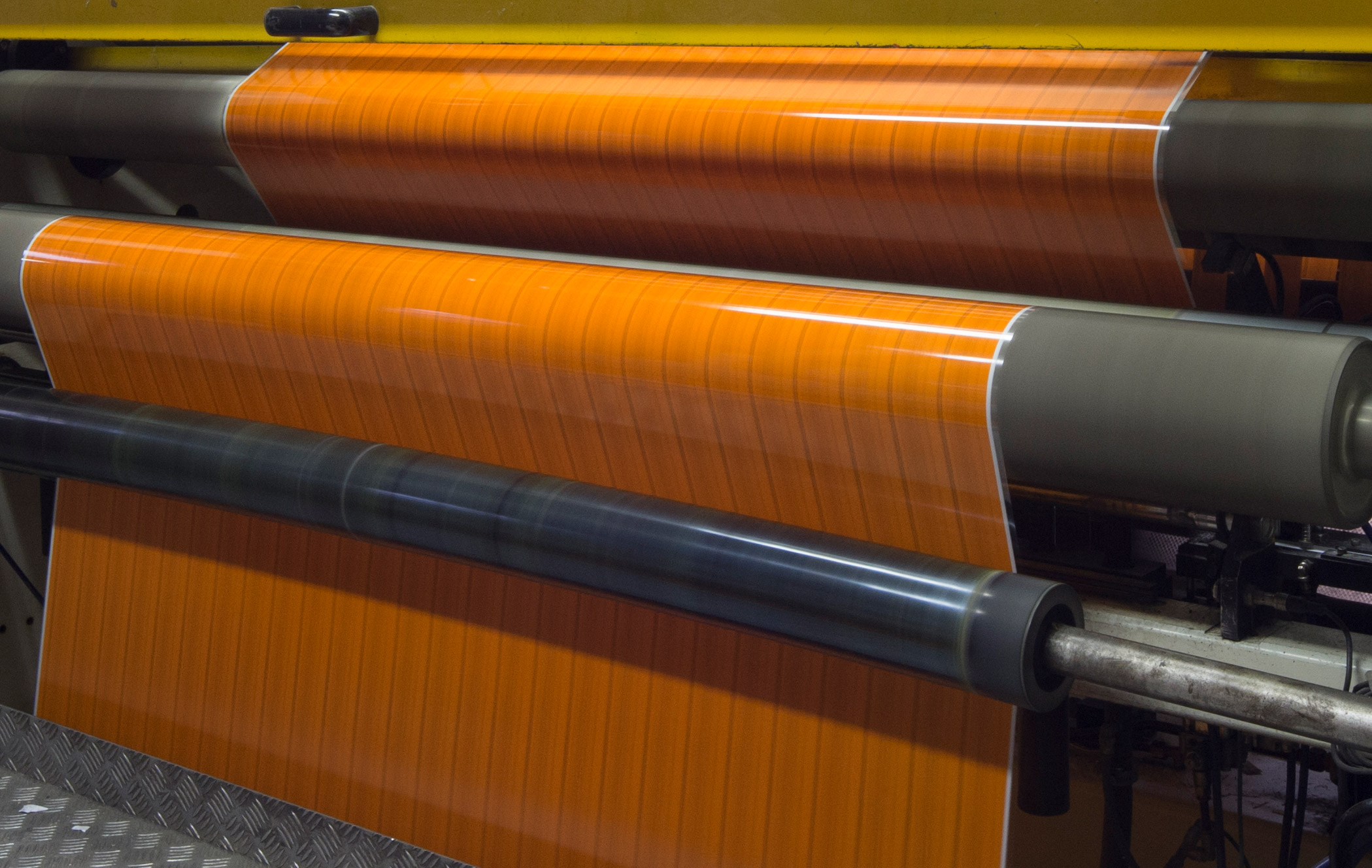

Our continuous growth over time allowed us to achieve a policy of constant technological innovation. The synergy between our team and the technological capital built up, let find solutions to the different needs by offering quality products at moderate prices. Our production can rely on two technologies of adhesive coating.

PRODUCTION

MATERIAL

With new machines and expertise, FILMAC offers a big range of products, from packaging tape

to masking, fixing and special tapes, offering professional solutions even to the most difficult

applications.

DISPERSION ACRYLIC:

Polymers emulsified or dispersed in water, with the possible addition of additives.

SYNTHETIC RUBBER:

Melting and hot mixing of gums and resins, hydrocarbon and natural, with the possible addition of additives.

SANDWICH PRINT

Innovation means pay attention to research and development, making constant investments in one’s firm in order to achieve technologically advanced products. In response to a continuous marker demand for a qualitative standard, FILMAC proposes the ‘Sanwich print’, a process which allows us to insert the ink between film and adhesive; this make particularly clear, bright and indelible prints obtained.

An alternative to petroleum-derived materials for a better world.

PLA offers multiple options in terms of the end of life. Besides landfilling, there are other solution which allow to recover the energy value of PLA and minimize the impact on our environment.

Once converted into packaging FILMAC BIO TAPES film can be industrially composted an will disintegrate in six months into C02, water and humus, a soil nutrient.

FILMAC BIO TAPES can also be mechanically and chemically recycled, as well as incinerated.

A PLA bioplastic made from dextrose manufacturing generates 80% LOWER GREENHOUSE GAS EMISSIONS than traditionally plastics.